What Is Metal Etching

Metal etching is a diverse and intricate technique used to create designs and patterns on the surface of metals through various chemical, electrolytic, or mechanical processes.The origins of metal etching can be traced back to ancient civilizations, where artisans employed rudimentary techniques to inscribe patterns and images onto metal surfaces. These early methods typically involved using sharp tools to carve designs into metal surfaces, which were then treated with acids or other corrosive substances to accentuate the etched patterns.

During the Middle Ages, metal etching saw significant advancements, particularly in Europe. Early examples of metal etching can be found in the decorative artifacts of ancient Egypt, Greece, and Rome.Artisans began using more sophisticated methods, such as applying wax or resin coatings to metal surfaces before etching. This period also saw the development of techniques like niello, where designs were incised into metal and then filled with a dark, contrasting substance. The Renaissance period marked a significant turning point in the history of metal etching, with artists like Albrecht Dürer and Rembrandt van Rijn mastering the technique to produce detailed and intricate works of art.

How Metal Etching Works – Metal Etching Process

Metal etching is a process that involves removing material from the surface of a metal to create intricate designs, patterns, or text. This technique can be carried out using various methods, including chemical, electrolytic, and mechanical processes. Each method has its own unique procedures and applications, allowing for a wide range of possibilities in terms of design complexity, precision, and material compatibility.

As technology continues to advance, the possibilities for metal etching will expand, ensuring its continued relevance and utility in a wide range of fields.

Chemical Etching Process

Chemical etching, also known as acid etching, is one of the most widely used methods for metal etching due to its simplicity and effectiveness. Here’s a step-by-step overview of how chemical etching works:

- Cleaning the Metal Surface: The metal surface is thoroughly cleaned to remove any oils, dirt, or oxidation. This ensures that the resist adheres properly to the metal.

- Applying the Resist: A resist material, such as wax, varnish, or photoresist, is applied to the areas of the metal that are not to be etched. The resist protects these areas from being exposed to the etchant.

- Immersion in Acid: The metal piece is immersed in an acid bath. Common acids used include ferric chloride, nitric acid, or hydrochloric acid. The acid reacts with the exposed metal, dissolving it and creating the etched design.

- Control of Etching Depth: The depth and clarity of the etch can be controlled by varying the concentration of the acid and the duration of exposure. Agitation of the acid bath can also ensure even etching.

- Removing the Resist: After the desired etching depth is achieved, the metal is removed from the acid bath. The resist is then stripped off using a solvent, revealing the etched design.

- Cleaning and Finishing: The etched metal is cleaned to remove any residual acid and resist material. Additional finishing processes, such as polishing or patination, may be applied to enhance the appearance of the etched design.

Electrolytic Etching Process

Electrolytic etching, or electro-etching, utilizes an electric current to etch the metal. This method is known for its precision and ability to produce intricate details without the use of harsh chemicals.

- Cleaning the Metal Surface: Similar to chemical etching, the metal surface is cleaned to ensure proper adhesion of the resist.

- Applying the Resist: A resist material is applied to the areas of the metal that should remain unetched.

- Setting Up the Electrolytic Cell: The metal piece to be etched is connected to the positive terminal (anode) of a power supply, while a cathode (usually made of a conductive material) is connected to the negative terminal. Both are immersed in an electrolyte solution.

- Applying the Electric Current: When an electric current is passed through the electrolyte solution, metal ions are removed from the anode (the metal piece), creating the etched design. The electrolyte solution can vary depending on the metal being etched.

- Removing the Resist: The resist is removed using a suitable solvent, revealing the etched design.

- Cleaning and Finishing: The etched metal is cleaned and any additional finishing processes are applied as needed.

Mechanical Etching Process

Mechanical etching involves physically removing material from the metal surface using tools or machinery. This method can be labor-intensive but allows for a high degree of control and detail.

- Design Transfer: The design to be etched is transferred onto the metal surface, often using a stencil or a direct drawing method.

- Engraving Tools: Hand tools such as engraving needles, chisels, or rotary tools are used to carve the design into the metal. CNC (Computer Numerical Control) machines can also be employed for precision and consistency.

- Depth Control: The depth of the etch is controlled manually or by adjusting the settings on CNC machines.

- Cleaning and Finishing: The etched metal is cleaned to remove any debris or residual material. Finishing processes such as polishing or applying a patina may be used to enhance the final appearance.

Acid Etching Process

The acid etching process involves several key steps, each essential for achieving a successful etch.

- Cleaning the Metal Surface: The metal must be thoroughly cleaned to remove any oils, dirt, or oxidation. This ensures that the resist adheres properly and that the etching is even and precise.

- Applying the Resist: The resist material is applied to the areas of the metal that should not be etched. This can be done using brushes, rollers, or by immersing the metal in a resist solution. For photoresists, the metal is coated with the resist and then exposed to UV light through a patterned mask, hardening the resist in the exposed areas.

- Immersion in Acid: The metal piece is submerged in an acid bath. The type of acid used depends on the metal being etched. The acid reacts with the exposed metal, dissolving it and creating the etched design.

- Controlling Etching Depth: The depth and clarity of the etch can be controlled by adjusting the concentration of the acid, the duration of exposure, and the temperature of the solution. Agitating the acid bath can help ensure even etching.

- Removing the Resist: Once the desired etching depth is achieved, the metal is removed from the acid bath. The resist is then stripped off using a suitable solvent, revealing the etched design.

- Cleaning and Finishing: The etched metal is cleaned to remove any residual acid and resist material. Additional finishing processes, such as polishing, patination, or coating, may be applied to enhance the appearance and durability of the etched design.

Metal Etching Services – Rapid Etching Prototyping Company China

If you want to find a cost-effective and rapid metal etching prototyping solution for your manufacturing needs, BE-CU can be a good choice for you.

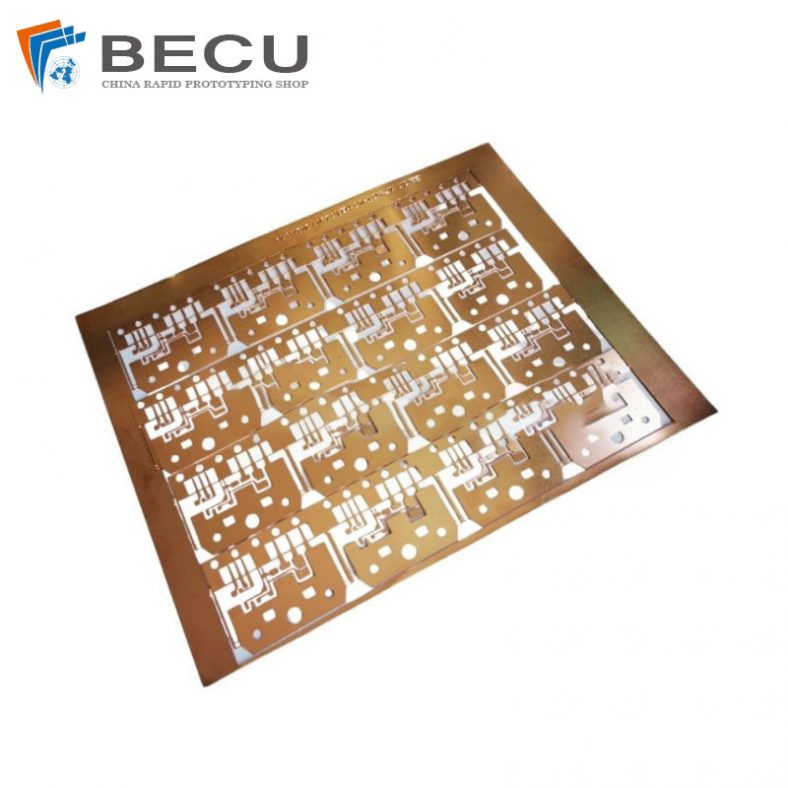

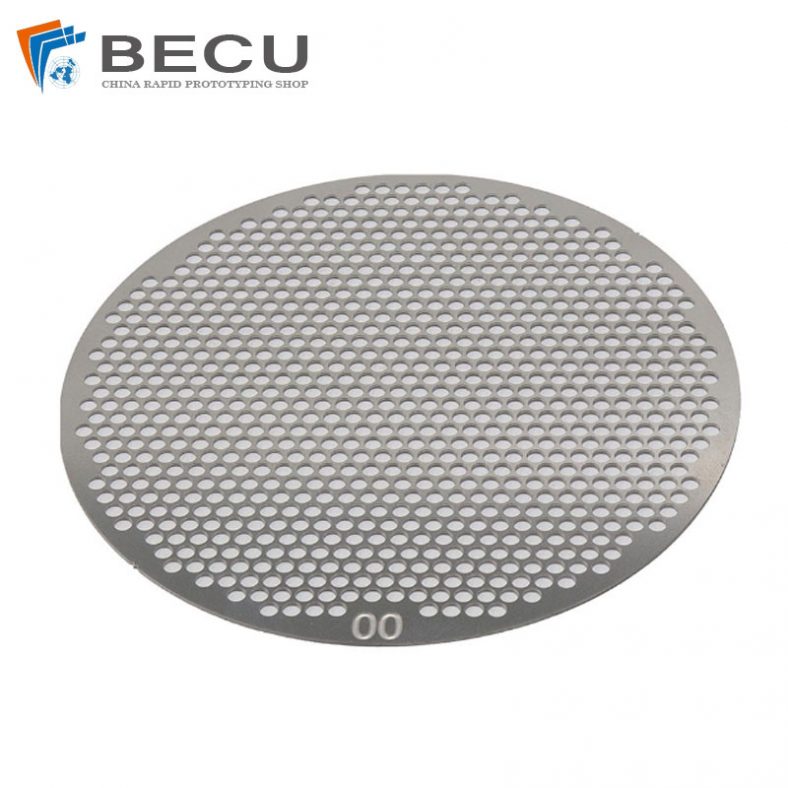

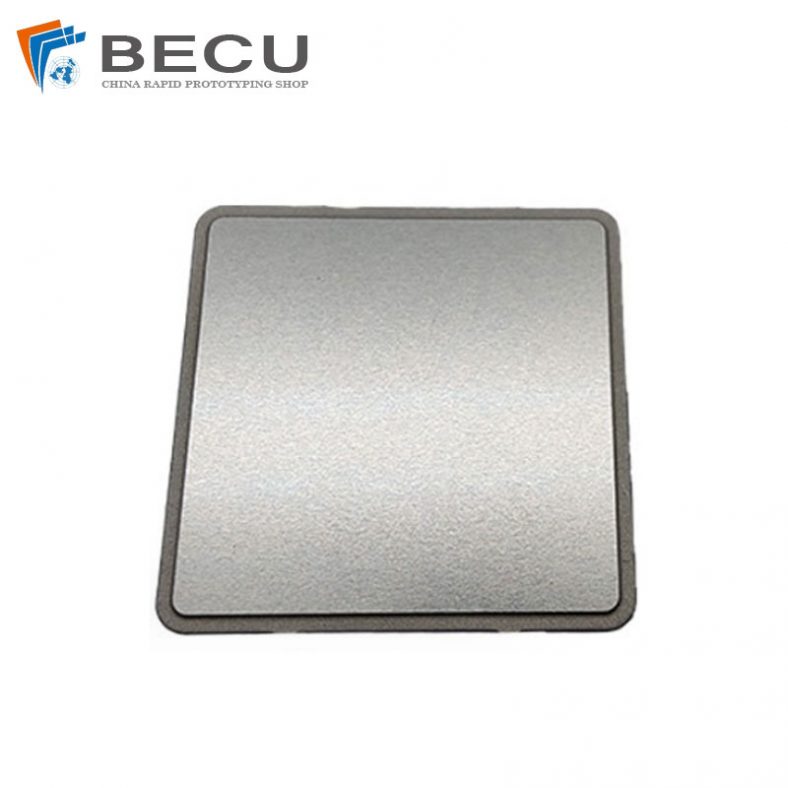

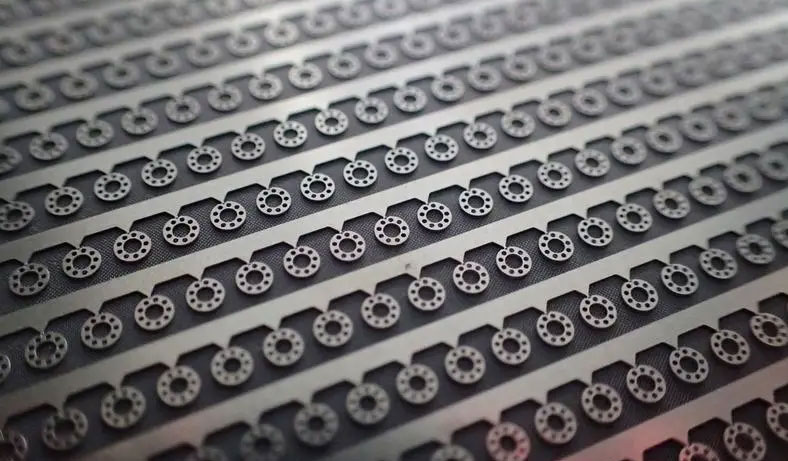

Based on extensive experiences and professional expertise, our metal etching services are available for both prototypes and low to high-volume production runs. Working with BE-CU, the most advanced fabrication machinery allows us to fabricate end-use metal etching parts and cut various materials with high efficiency while maintaining premium quality, which saves money and time for our clients significantly.

Our custom metal etching service provides durable and affordable metal etching components that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, marine, and more industries. Sheet materials or stock are usually cut using a high-powered CNC laser or waterjet. Capable of handling parts sizes from 0.02 in. dia. to 24 x 60 in. and 0.001 to 0.08 in. thickness. According to your requirements and applications, we’ll offer suggestions for product design, suitable materials, and the most cost-effective methods for sheet etching. Other services include blasting, cleaning, CNC machining, stamping, laser machining, bending, water jet machining, electronic and laser welding, heat treating and electro polishing. Minimal cost, time, and best quality are our purposes.Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.

Precision Etching Material – Metal Etching Products

The choice of materials for precision etching plays a crucial role in the success of the process, as different materials respond differently to etching techniques.A wide range of materials and surface finishes enable us to make the best option for your project, the raw materials include but are not limited to stainless steel, aluminum, brass, copper, steel, plastic, etc. Polishing, painting, sandblasting, plating, anodizing, powder coating, and other finishing services bring better surface quality to your parts.

Stainless Steel is iron-based alloys containing Chromium and Nickel (and to a smaller degree, other metals) to provide physical strength and corrosion resistance.BE-CU ETCH chemically etches 301, 302/304, 316/316L, and 400 series stainless steel parts for a variety of industries.

Aluminum is a lightweight, highly conductive, reflective, and non-toxic metal. Its durability and corrosion-resistant properties make Aluminum chemical etching ideal for components in a variety of industries, including transportation, electronics, cookware, packaging, and construction.

Copper chemical etching is an excellent process for applications in the electrical and electronic industries. This soft metal possesses high thermal and electrical conductivity and is one of the easier metals to photo-chemically machine or etch.BE-CU’s etching process produces designs that can withstand harsh indoor and outdoor environments.

Brass is a binary alloy composed of Copper and Zinc. It is similar to Bronze and valued for its workability, hardness, corrosion resistance, and attractive appearance. The metal is easily machined and formed into desired shapes while retaining high strength. Acid etching for Brass components is ideal for the automotive, artisanal metalworking, music, appliance, and sanitary industries.

Titanium chemical etching is an excellent process for components that require corrosion resistance in a variety of industries.Titanium is a corrosion resistant metal with strong and lightweight properties. Commonly used in applications in aerospace, medical implantable devices, automotive, and many other industries.

Molybdenum plate is very hard, yet also ductile, possessing toughness superior to tungsten. It exhibits a high elastic modulus, while tungsten and tantalum only boast high melting points. Molybdenum plate finds utility in many specialty steels.

Custom Etching Parts Online – Choose the Best Metal Etching Supplier

Currently, our Metal Etching parts are exported to America, Canada, Australia, United Kingdom, Germany, France, Sout Africa, and many other countries all over the world. We are ISO9001-2015 registered and also certified by SGS.

Our custom Metal Etching fabrication service provides durable and affordable castings that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, marine, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.Contact us or Email [email protected] to see how our people, equipment and tooling can bring the best quality for the best price for your metal etching project.