What Is Laser Cutting

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications. It works by directing the output of a high-power laser, usually through optics, into a material.Laser cutting allows great flexibility, accuracy and top quality. It can cut very complex shapes with remarkable speed.You can create custom laser cutting service for your applications in BE-CU. We provide laser cut almost anything you can draw, whether it is square, oval, triangular, trapezoidal, holes, curves shapes, geometric shapes, irregular shapes and more.

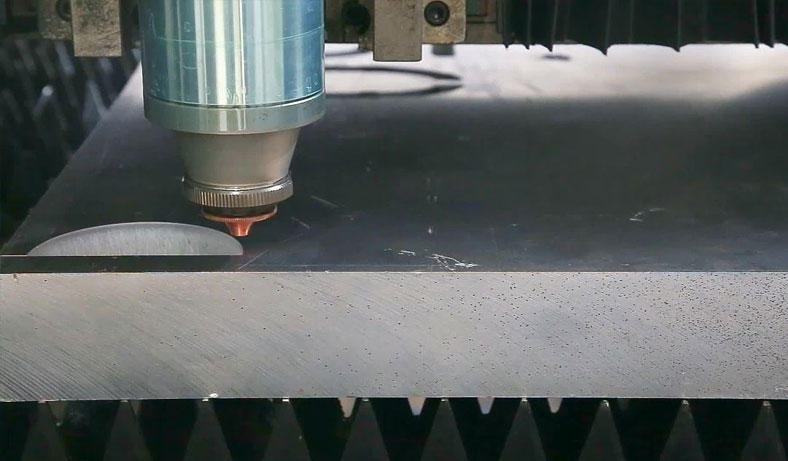

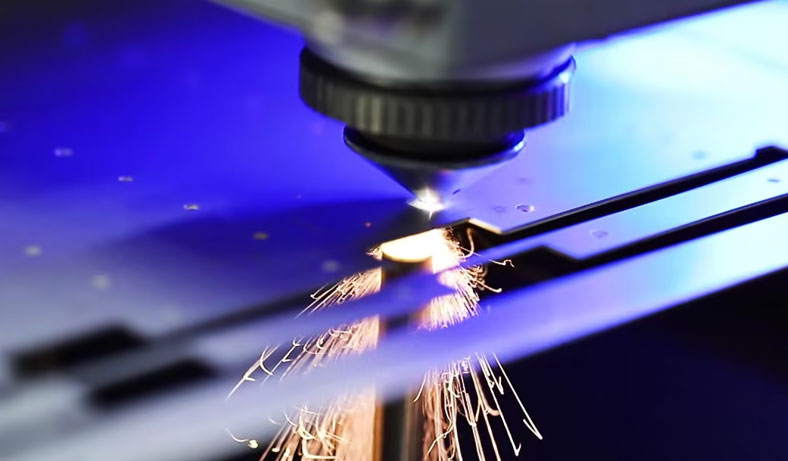

How Laser Cutting Works

Laser cutting is a precise and efficient method for cutting materials using a focused laser beam. Here’s a step-by-step breakdown of how the process works:

- Laser Source: The laser beam is generated by a laser source (resonator). It can be a gas laser (such as CO2), fiber laser, or crystal laser (such as Nd:YAG).

- Beam Delivery: The laser beam is directed by a series of mirrors or through a fiber optic cable to the cutting head.

- Focusing: The laser beam is focused on the material by a lens or a specialized mirror. This focus makes the beam extremely concentrated and capable of melting, burning, or vaporizing the material.

- Cutting: The focused laser beam is directed at the material, causing it to melt, burn, or vaporize in a controlled manner, following a predefined path. The cut edge can be very precise and clean, with minimal material deformation.

- Assist Gas: During the cutting process, an assist gas (such as oxygen, nitrogen, or air) is often used to blow away the molten material and to protect the cutting area.

Laser Cutting Service

BE-CU metal co., limited is a professional China laser cutting company provides superior precision pipe and plate laser cutting services with advanced machines including 7-axis (3D) and flat CNC laser cutter from the general fiber laser to accomplished machinists. Laser cutting services by BE-CU ensure your growing needs never outpace your production capabilities. Our Project Engineers are ready to assist in planning and execution, making certain your projects are completed cost-efficiently and to high quality standards.

Our high-quality rapid laser cutting products are involved in the field of automation design, lockset, automobile parts machining, machinery milling, defense industry, medical equipment, lighting parts machining, etc. Send your inquiry or drawing fast to get an online laser cutting quote.

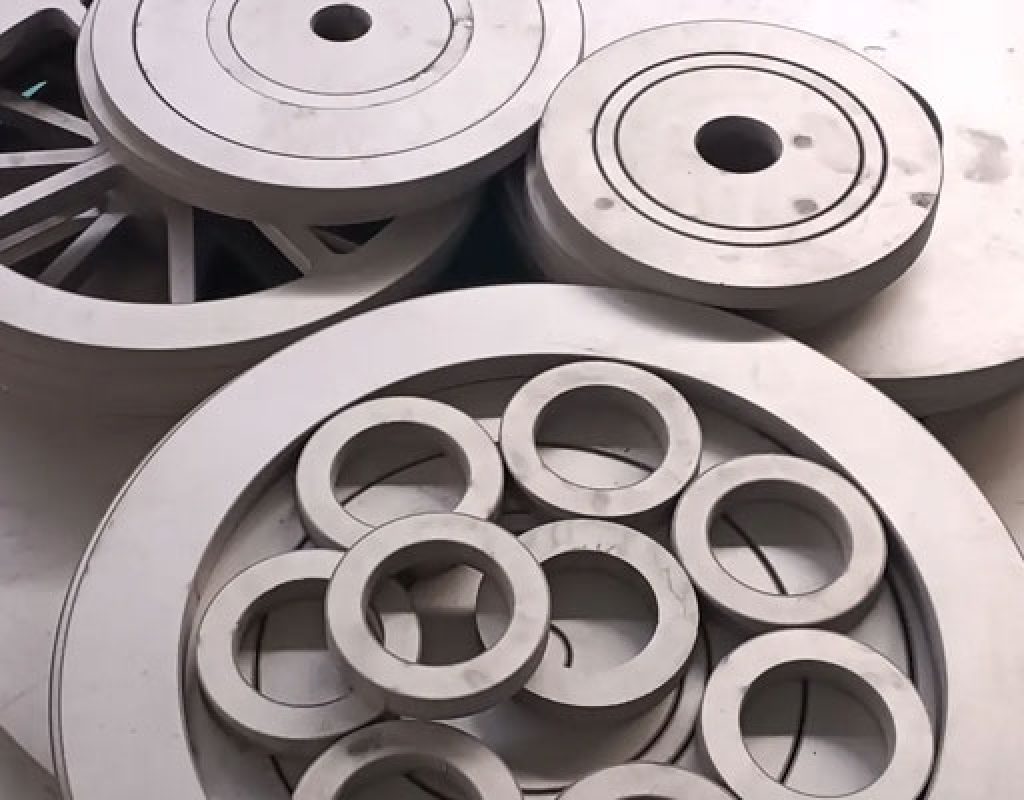

Pipe Laser Cutting

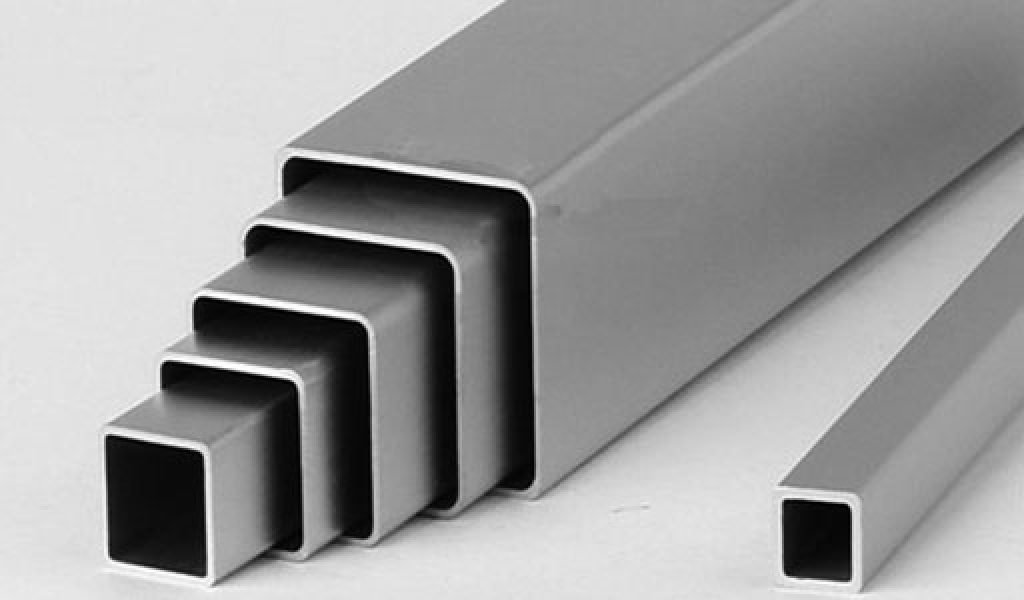

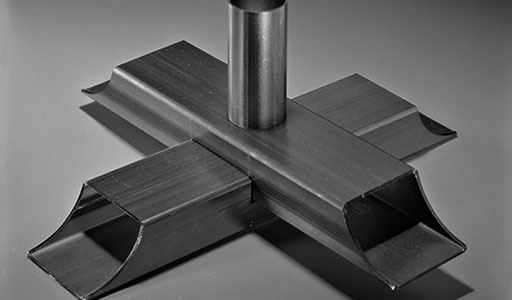

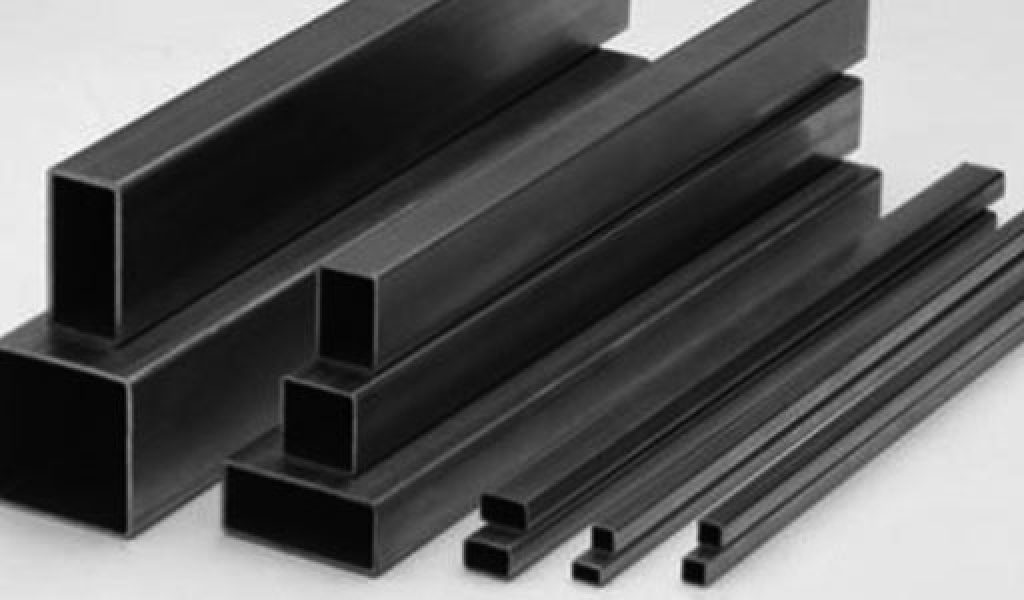

With strong capabilities and extensive experiences, we can provide top-grade but cost-effective custom ISO 9001:2015 certified pipe laser cutting services from China,materials handled include aluminum, mild steel and stainless steel and more.

Capabilities include cutting of round, square, rectangular and oval pipes up to 6 in. dia. Other services such as fabricating, CNC machining, manual and robotic welding and sheet metal forming services are also available.

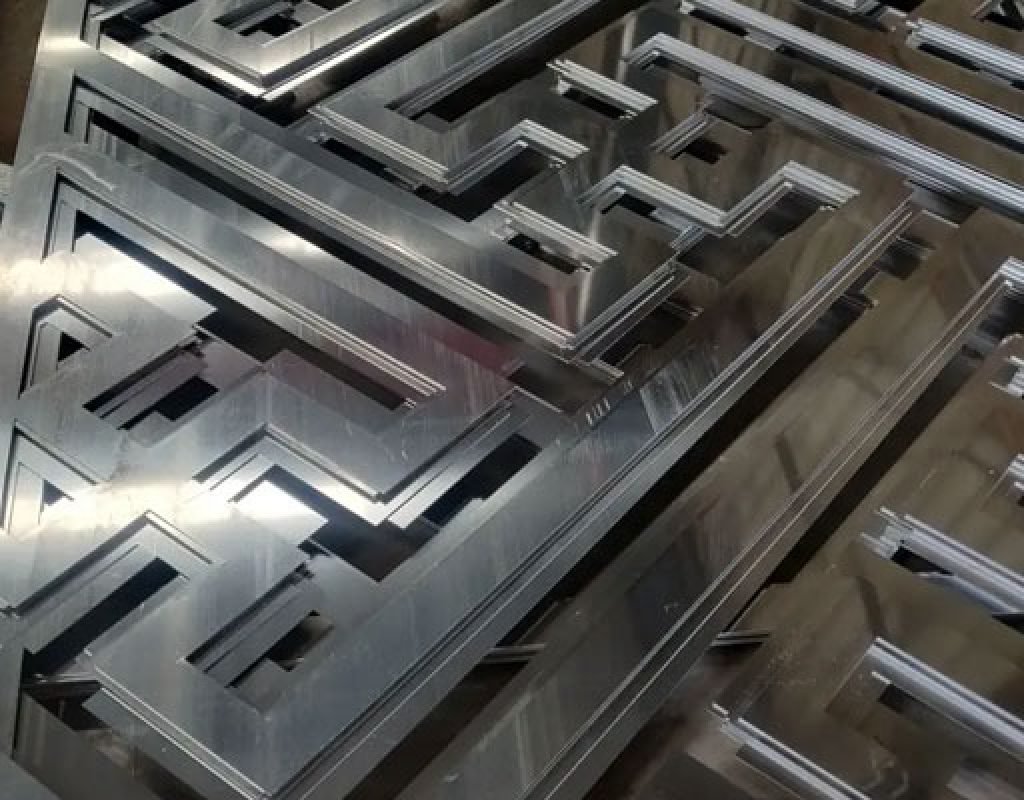

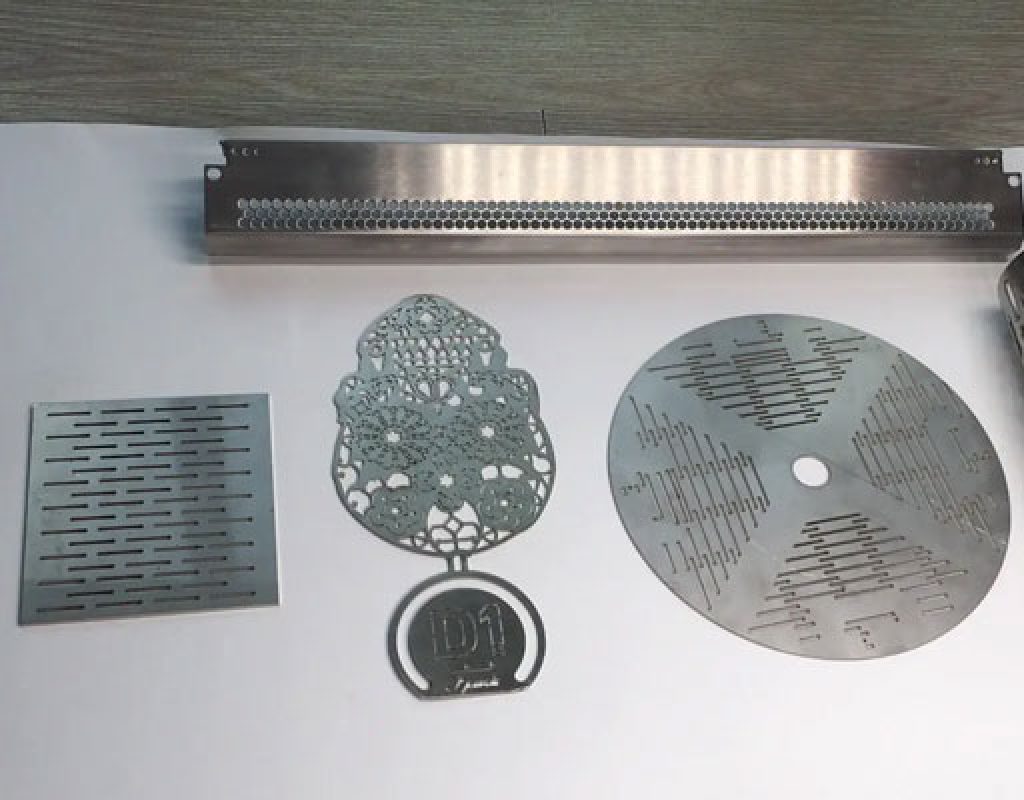

Sheet Metal Laser Cutting

Our advanced sheet metal laser cutting routinely works with a wide variety of materials, ranging from aluminum, brass, bronze, copper, nickel, stainless steel, niobium, and titanium. We can always choose a suitable precision plate laser cut process to reach your requirements. Capable of cutting parts up to 240 in. size and +/- 0.002 in. tolerance. Secondary services such as finishing, laser marking, deburring, and hardware installation are also provided.Secondary services such as finishing, laser marking, deburring, and hardware installation are also provided.

Our custom plate laser cut services ensure that our customers receive the highest quality sheet metal parts. Send your inquiry or drawing fast to get an online CNC quote.

Laser Cutting Materials

BE-CU customers have the freedom to specify components in hundreds of different metals and alloys, while enjoying a single high standard of confidence in our ability to deliver as promised.

Upholding this standard requires an exceptional commitment to manufacturing resources.Behind it all is a staff of engineers and machining experts with a 30+ year track record of adapting to both new alloys and tried-and-true materials. Therefore, we include a list of most common metals with their maximum recommended thickness for getting the best quality results:

- Mild steel – up to 30 mm

- Stainless steel – up to 30 mm

- Special steels (Hardox, Strenx, etc.) – up to 20 mm

- Coated steel – up to 5 mm

- Aluminium – up to 30 mm

- Copper alloys – up to 12 mm

Lasers are suitable for cutting a variety of non-metal materials. These include MDF, acrylic, wood, card, paper, etc. Unfortunately, we do not offer such cutting services at the moment.

Laser Cutting FAQs

You asked the most important laser cutting frequently asked questions and we have the answers, direct from the laser cutting experts.

What standard do you follow?

Can you provide material certificates?

Do you cut anything besides metal?

What are the lead times?

Do you provide manufacturing consultation?

The main advantages of laser cutting

Precision – Accuracy of+/- 0.1 mm for laser cut parts gives the possibility to really cater to your most demanding needs. This kind of precision also ensures high quality.

Repeatability – +/- 0.05 mm ensures close to identical details.

Speed – Laser cutters are known for their speed, especially when cutting thin metal sheets.

Saves money – The machines are getting more energy efficient. Shuttle tables reduce the need for handling which means less need for manual labour. Smaller manufacturing costs result in lower total costs for the buyer.

Saving time – CNC laser cutting is automated. Therefore, it is the machinery that reads the drawings. The drawings only need to include cutting lines. This saves a lot of time in the drawing-room.

Small areas of HAZ – The heat affected zone is an unwanted byproduct of thermal cutting methods. As laser cutting has a small cutting kerf, the heat is not dispersed as heavily as with other cutting methods, leaving a smaller HAZ.